Advancing Circular Economy with 3devo’s Desktop Recycling Solutions

In today’s environmentally conscious world, the concept of a circular economy is rapidly gaining traction across industries, driven by a global urgency to reduce waste

In today’s environmentally conscious world, the concept of a circular economy is rapidly gaining traction across industries, driven by a global urgency to reduce waste

In the realm of hospitality, standing out through innovation and unique service offerings isn’t just beneficial—it’s essential to thriving in an increasingly competitive market. At

The current global momentum towards sustainability and eco-friendly initiatives has prompted a search for innovative, disruptive technologies that allow industries to adopt a circular economy—an

In today’s competitive landscape, businesses and universities are increasingly seeking ways to improve their environmental footprint, reduce waste, and promote a circular economy. One such

The rapid growth and evolution of 3D printing technology have opened numerous doors in various sectors. One such innovation is the advent of 3D food

In recent years, 3D printing technology has proliferated across various industries, shaping innovative solutions and transforming age-old practices. One domain where this creative force is

As stewards of innovation and sustainability, we find ourselves at the forefront of transformative technology that not only promises to revolutionise industry practices but also

In the age of sustainability and circular economy, innovative technologies are paving the way for more responsible manufacturing and resource utilisation. A key contributor in

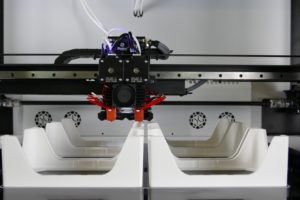

As the 3D printing industry continues to evolve and expand, innovative companies like Anisoprint are leading the charge in the development of groundbreaking technologies that

Manufacturing complexities in industries like aerospace, automotive, and space have always called for innovative solutions. The constant quest for lighter, stronger and more flexible materials

In the ever-evolving world of 3D printing, Natural Machines has emerged as a pioneer, bringing revolutionary advancements to schools, aged care facilities, and the hospitality

The world is moving towards a more sustainable future, and the adoption of circular economy principles is gaining traction in various sectors, including the 3D

In recent years, the boundaries of what is possible in culinary practices have been pushed to new heights as innovative technologies such as 3D food

In a world where innovation, efficiency, and sustainable practices are of paramount importance, industries spanning aerospace, automotive, and manufacturing are continuously searching for groundbreaking technologies

The food industry is constantly evolving, always on the lookout for innovative ways to deliver more efficient, sustainable, and customizable solutions. Enter Natural Machines and

It’s no secret that the world is in dire need of sustainable solutions to combat the escalating environmental crisis. Innovative technologies have stepped into the

In today’s fast-paced and ever-evolving food landscape, there is a growing need for innovative solutions that not only elevate the culinary experience but also address

In the ever-evolving landscape of advanced manufacturing, industries such as space exploration, automotive, aerospace, and manufacturing are constantly searching for new technologies that offer increased

The growing demand for sustainable solutions is driving the need for innovative approaches to material usage and management in numerous sectors, including manufacturing and education.

As part of our commitment to offering top-quality, environmentally-conscious 3D printing solutions, we are proud to partner with brands that share our values and principles.

In today’s fast-paced world, the demand for innovative, efficient, and sustainable food solutions is higher than ever. From addressing the challenges of feeding growing populations

The advent of 3D printing has undoubtedly revolutionised the way we create and innovate, bringing unlimited possibilities to industries around the globe. As this technology

As industry professionals continue to push the boundaries in search of more advanced manufacturing solutions, a growing desire to develop lightweight, robust alternatives to traditional

The world of 3D printing has advanced by leaps and bounds over the years, transforming not only industrial manufacturing but also the culinary landscape. One

The fusion of culinary artistry and cutting-edge technology is reshaping how we perceive, experience, and create food. At the forefront of this innovation lies 3D

The healthcare industry is constantly evolving and adopting new technologies to improve patient care and ensure the best possible outcomes. Among the most revolutionary technologies

Sustainability and environmental responsibility are becoming increasingly important factors in the world of manufacturing, and the 3D printing industry is no exception. As global demand

The rapid advancement of 3D printing technology has produced a significant and transformative impact on various industries. Healthcare, in particular, stands to benefit considerably from

Amidst the undeniable advancements 3D printing has brought to various industries, it is critical to consider the technology’s environmental impact and assess potential solutions promoting

While the applications of 3D printing technology are diversely impacting industries such as automotive, aerospace and healthcare, the world of art and design is another

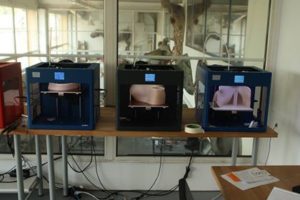

The intersection of 3D printing technology and education is a dynamic and rapidly changing landscape, presenting a wealth of opportunities to empower students and educators

In today’s competitive business landscape, companies are constantly seeking new ways to streamline their operations, improve efficiency, and reduce time to market. Enter 3D printing

The world of 3D printing is continuously evolving, offering newfound opportunities for businesses to grow and thrive. As a result of its increasing reliance on

In recent years, 3D printing has emerged as a ground-breaking technology, disrupting traditional manufacturing processes and driving innovation across the globe. As it gains traction,

3D printing technology is rapidly gaining traction within the aerospace industry as manufacturers and engineers recognise the potential for innovation and efficiency afforded by this

As society grows increasingly conscious of the environmental and ethical challenges facing the fashion industry, the demand for more sustainable, innovative, and responsible production methods

The realm of 3D printing is endless, with innovations and breakthroughs happening across various industries, constantly transforming how we approach different challenges. One area witnessing

The healthcare industry is undergoing a remarkable transformation thanks to the incredible advancements in 3D printing technology. With its ability to create highly accurate and

The automotive industry has long been an arena for technological advancement, continuously driving progress and adaptation to emerging technologies. One of the latest innovations making

The landscape of education is constantly evolving as new technologies and methodologies emerge, reshaping how we approach teaching and learning. In recent years, 3D printing

The continuous quest for improved healthcare solutions and the demand for personalised, patient-centric treatments drive innovation within the medical sector. One of the most transformative

The construction industry is at the cusp of a significant transformation, driven by the incredible potential of 3D printing technology. Offering substantial advantages in terms

Fashion is often regarded as a form of self-expression, and with technology continuously changing the way we perceive and interact with the world, the fashion

Technology has always played a vital role in the evolution of healthcare. From the invention of the stethoscope in the early 19th century to the

The journey of 3D printing technology has been a remarkable one, with its incredible potential unlocking new prospects and applications across multiple industries. One of

The world, as we know it, is undergoing a technological revolution, with several industries incorporating modern techniques to optimize their operations. The construction industry is

The automotive industry is in a constant state of evolution, with manufacturers striving to develop new technologies and designs that improve performance, safety, and efficiency.

Researchers are working harder to develop delicious and environmentally friendly substitutes for traditional seafood as worries about unsustainable fishing methods and their effects on the ecosystem continue to increase.

Although the refrigerated grocery store aisles may be stocked with many different animal substitutes, there are still few options for plant-based seafood.

The effects of overfishing, together with concerns about contamination and ethical issues, have increased consumer demand for seafood substitutes that may both appease palates and protect the seas.

A team from the National University of Singapore has reportedly grabbed the lead, displaying their creative method for producing alluring vegan seafood that not only tastes great but also closely resembles the nutritional profile of genuine fish.

Innovation fuels progress, and in today’s rapidly evolving world, the automotive industry is no exception. When it comes to advancements in automotive engineering, 3D printing

A team of researchers at Edith Cowan University in Australia is exploring an innovative way to boost nutrition for vulnerable populations – using 3D printing technology to create nutrient-packed “meals” out of pureed fruits, vegetables, and other ingredients. Their goal is to find new solutions for groups like elderly nursing home residents, schoolchildren, and military personnel who often struggle to get adequate nutrition from traditional meals.

The healthcare industry is constantly evolving, driven by the need to improve patient care and outcomes through technological advancements and innovative approaches to treatment. One

What distinguishes them from other Rapid Manufacturing facilities is their commitment to the protection of people and the environment, which has allowed them to become category leaders. Their project components are composed of 85% to 90% recycled materials, such as plastic bottles and fishing wires.

On the set of Blade Runner 2049, Craftbot made an impression. Iván Pohárnok, a famous Hungarian special make-up artist who works at Filmefex Studio, employed 10 Craftbot Plus 3D printers in the Hollywood blockbuster to construct incredibly realistic replicant bodies.

Based in Cornwall, UK, Michael Hunt aka ‘Mike3D’ provides complete 3D printing solutions for a variety of industries. In addition to his YouTube appearances, Mike runs his 3D printing his Cornwall and his 3D manufacturing facility offers multiple options for customizing bespoke and bespoke projects. I’m here. Craftbot was delighted to have his 3D printer in-house selected for one of Mike’s exciting brand collaborations. Mike said using his Craftbot, which can print advanced thermoplastics and materials, was a natural choice.

Dr. Alexis Dang, MD, is an orthopaedic surgeon from San Francisco, California and an Associate Professor of Sports Medicine at the University of California, San Francisco Department of Orthopaedic Surgery and the San Francisco VA Health Care System. Alexis has been in practise since 2004 after graduating from the University of California, San Francisco, School of Medicine. Dr. Dang has developed 3D printing tools for the instruction, scientific, and therapeutic uses at the University. He is a co-founder of Edge Labs that began at the Department of Orthopaedic Surgery as well as UCSF CA3D+ programme aimed to increase 3D printing and AR/VR across campus.

The field of medical and healthcare has been witnessing groundbreaking developments ever since its inception. Among these advancements, one significant innovation is 3D printing, which

Global urbanisation and the ever-increasing demand for affordable, sustainable housing solutions have spurred innovation within the construction industry. Among the groundbreaking technologies shaping the future

The world of 3D printing has seen extraordinary growth and evolution, bringing forth numerous innovative applications and advancements that have the potential to reshape various

In recent years, 3D printing has revolutionised the way we approach product design. This innovative technology has made it possible to create prototypes and products

3D printing technology has revolutionised the manufacturing industry, and its popularity is rising in Australia. The right filament selection has become increasingly crucial with the

Product design firms are tasked with creating innovative and functional products that meet the needs and preferences of their clients. In recent years, 3D modelling

3D printing services have revolutionised how industries operate, from healthcare to manufacturing. The technology has enabled businesses to improve efficiency, reduce costs, and enhance product

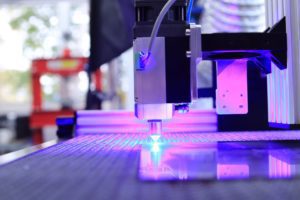

Additive manufacturing (AM), also known as 3D printing, refers to the creation of three-dimensional objects by adding material layer by layer. Since its inception, AM

Art has always been a reflection of the time and culture it comes from, and with the rise of technological advancements, artists have been able

When buying a 3D printer, printing precision is one of the most important factors to consider. The ability of a 3D printer to produce high-quality

In a world driven by innovation and boundless imagination, 3D printing has emerged as a transformative tool, empowering individuals to transform their ideas into tangible creations. Australia, with its vibrant artistic community and innovative spirit, has embraced this technology to unlock new realms of creativity. In this blog post, we invite you to explore the exciting world of 3D printing in Australia, showcasing local artists, designers, and makers who have harnessed its power to unleash their creative potential. Join us as we delve into inspiring stories and discover how you too can embark on a journey of artistic exploration with 3D printing.

In a world grappling with environmental challenges, it’s crucial to embrace technologies that can pave the way for a sustainable future. Enter 3D printing, a revolutionary technology that has captured the imagination of innovators and environmentalists alike. In this blog post, we will explore how 3D printing is driving a green revolution in Australia, promoting sustainability through waste reduction, recycling initiatives, and localized production. Join us as we uncover the profound environmental benefits of 3D printing and its potential to shape a greener tomorrow.

3D printing has rapidly grown in popularity over the past few years and has become a must-have tool for many industries. From prototyping to producing

Welcome to the world of 3D printing, where imagination takes shape and innovation knows no bounds. Australia has been quick to embrace this transformative technology, propelling the nation into a new era of manufacturing, design, and creativity. In this blog post, we’ll dive into the rise of 3D printing in Australia and uncover the myriad opportunities it presents for individuals and businesses alike. From local success stories to accessible resources, let’s explore how 3D printing is revolutionizing the way Australians create and innovate.

Generative design is a powerful technique used in 3D printing that allows you to create complex and intricate designs with ease. This method involves using algorithms to create a design based on specific input criteria, such as material properties or manufacturing constraints. With generative design, you can quickly create designs that are optimized for 3D printing and meet your specific needs.

3D Printers are amazing devices, with almost limitless possibilities to create, iterate and prototype to your hearts content. However, just like their 2D counter part,

Computer-Aided Design (CAD) software is used to build digital 3D models for a number of applications such as 3D printing, engineering, and architecture. Some fundamental

Fused Deposition Modeling (FDM) 3D printing is a popular method that uses thermoplastic filament as the printing material. There are several different types of filament

The NASA EPSCoR award of $1.125 million is a partnership between UNO Biomechanics and Copper3D, a Chilean business that is a pioneer and worldwide leader

A Science Fiction Dream Coming True? Copper3D, A Chilean 3D Printing Filament Start-up, and the Internation Space Station (ISS) have gone into, what seems like

3D Printing could revolutionize Coral Reef Restoration. Learn about this innovative process and its potential implications for the future of coral ecosystems.

Every person who’s heard about 3D printing has thought ‘what if we could 3D print food?’. Today, this is no longer a question, but a reality.

3D printed furniture to help end the plastic waste problem, thanks to Circular Economy Just a few years back, 3D printing was unknown for most

Is 3D food printing merely a fancy way of automating piping bags? That analogy works occasionally. However, this is not always the case. Some individuals will comment that 3D food printing is simply automating a piping bag when they observe food being printed layer by layer. That is accurate in some situations, and it makes for a solid fundamental parallel.

CurifyLabs and Natural Machines established a strategic agreement to create a technology that allows for the creation of tailored medicines using 3D printing.

There is currently a lot of scientific evidence supporting the relevance of proper eating habits for health maintenance and disease prevention.

Copper3D, a Chilean and US-based 3D printing firm, employs nano-copper additions and adds antimicrobial qualities to polymers like PLA and TPU to make antibacterial 3D printed products. Copper3D, who have collaborated with NASA previously to explore microbiological hazards in space also started work on a project in their home in Chile.

Copper nanoparticles in PLActive are excellent at removing viruses, fungus, and bacteria while remaining safe for people. It is a low-cost, biodegradable material with thermoforming

Face masks were in low supply during COVID-19, despite the fact that they are a basic necessity for the majority of the world’s populations. The usage of these masks (or ones identical to them) on public transportation has also been advised by authorities in various locations. Although these masks are helpful, they nevertheless have a few drawbacks, including a poor lateral fit, a brief lifespan of just around 8 hours, and an even more serious issue. SARS-Cov-2 (COVID-19) and other respiratory viruses can survive for up to 72 hours on various surfaces.

The aerospace industry has been enthusiastic about composite materials and their use, as well as their disappointment. Composites have been used in jet aircraft for decades, but their design, manufacture, and post-processing have been treated the same as metals. Composites are a more difficult technology to design than metals because of their complexity. Because there is not much theory behind simulating or estimating the behaviour of composites, the same simple methods used for metals are applied to them. Fibre reinforced composites are directional by nature, whereas metals are omnidirectional, and all design methods are created for isotropic materials.

3D printing with continuous fibers is a new technology that is still improving and maturing. As an emerging additive manufacturing process, its versatility and potential are still being tested. So far, it has proven to be a useful tool for producing parts that have specific qualities – like flexibility, strength, or softness – that cannot be made as efficiently with other processes.

In general terms, Anisoprinting use a process of 3D printing using continuous synthetic fibers as a build material. The resulting composite materials have unique properties not possible with most other methods. In this post, we’ll explain who Anisoprinting is and how they use continuous fibers with other additive manufacturing techniques to produce objects with unique properties.

… The medical industry has always had a positive relationship with 3D printing, even before Covid-19 notably made headlines.

Professionals who need exquisite dexterity in their work may suffer physically from disorders like rheumatoid arthritis or accidents to their joints, which could possibly end their careers. However, there may be some hope in sight owing to a specialized cooperation from the Fraunhofer Institute, AI, and some good ol’ 3D printing.

3D printing is a fast-growing industry, and the 3D-printed ultrasound is no exception. A 3D ultrasound is an image of a fetus that has been created through a 3D printer. It can be used as a medical tool to diagnose abnormalities in the fetus, or it can be used as an educational tool to illustrate the development of the fetus over time.

Experts in regenerative medicine CollPlant have declared that their patented 3D bioprinted breast implants have passed animal testing. The implants made by CollPlant are bioprinted from “rhCollagen,” a plant-based substitute for human collagen, and are intended to encourage cell regeneration before slowly integrating into host tissues over time.

The business now intends to carry out additional research on implants that resemble “commercial-size items” before conducting human trials and bringing them to market after reporting “promising results” from its most recent tests.

A method for 3D bioprinting eye tissues utilising patient stem cells has been developed by researchers at the National Eye Institute (NEI) in the United States. The researchers claim that by using their method, which involves printing three different kinds of immature choroidal cells onto a biodegradable scaffold, it would be possible to produce an endless supply of tissues taken from patients. These, in turn, may enable medical professionals to comprehend the underlying mechanisms of prevalent degenerative retinal illnesses like age-related macular degeneration (AMD).

There has been some level of worry among writers that we might be the first profession to be replaced by AI since the most recent version of ChatGPT was launched a few weeks ago. Whether that worry is warranted is outside the purview of this post, but suffice it to say that we can now add 3D modellers to the list of potential job losers, as OpenAI has recently unveiled a comparable method that turns text into 3D models.

Hydrogels infused with fungus mycelia have been produced by researchers at the ETH Zurich in Switzerland as a method of 3D printing a self-repairing skin. If the fungal network is allowed to metabolise, the skin will heal itself when it is damaged, and it does this by ingesting nutrients. It is a living entity since it has the ability to undergo metabolism. It is the epitome of a cybernetic organism

The use of 3D printing, commonly referred to as additive manufacturing, has completely changed how we make and design physical products. But who created and pioneered this ground-breaking technology? In this article, we’ll examine the development of 3D printing throughout its history, from its infancy to the present, as well as some of the influential figures who have contributed to it.

The material that a 3D printer uses to build items is called filament.

Although there are other varieties of filament available, flexible filaments are becoming more and more common because of their adaptability and capacity to produce flexible, bendable, and robust items.

We will go through what flexible filaments are, the various kinds that are available, and some possible applications in this blog.

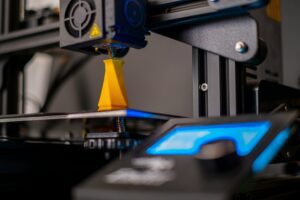

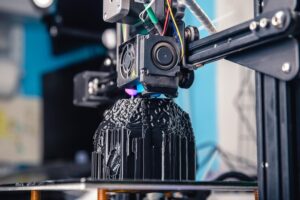

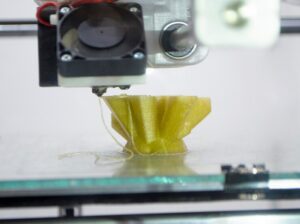

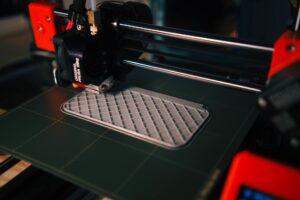

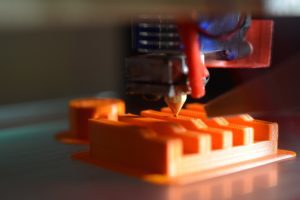

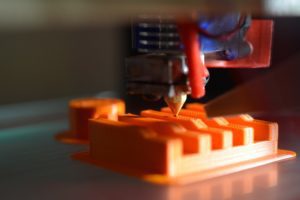

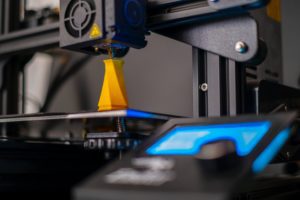

Making real products from digital models is a method known as 3D printing, commonly referred to as additive manufacturing.

3D printing creates products layer by layer as opposed to conventional manufacturing processes, which entail cutting, shaping, or moulding material.

This enables the construction of intricate interior structures and geometries that are not feasible using conventional techniques.

A tangible object can be created via 3D printing from a digital model.

Up until the object is finished, successive layers of a material, such as plastic or metal, are laid down to construct the object.

The digital model is divided into thin layers, each of which is printed separately to create the object layer by layer.

Additionally referred to as additive manufacturing, this process.

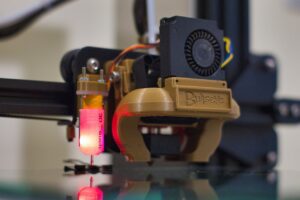

Fused Deposition Modelling (FDM), which is an extrusion-based process in which the material is melted and extruded through a nozzle to make the object, is the most popular 3D printing technique.

3D APAC Pty Ltd Copyright © 2023. All rights reserved