3devo is a tech company founded by young inventive engineers in the Netherlands. their mission centres on developing accessible and high-quality products to empower innovators and creators.

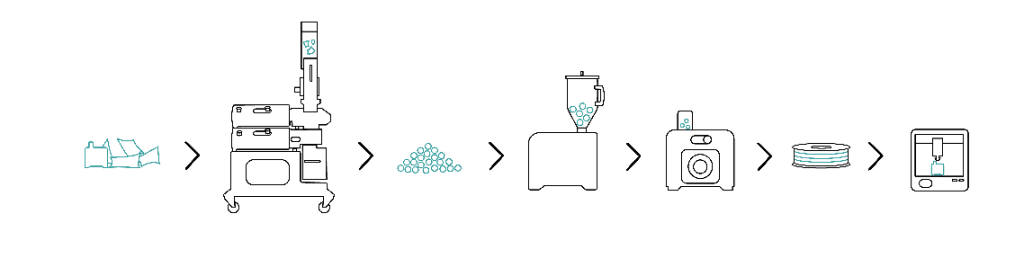

Back in 2014, we started tweaking our very first filament maker prototype. Along the way, many improvements have been made to what is known today as the Composer and Precision Filament Makers. But we didn’t stop there. We took the next step and decided to make it our priority to create products that fully covered the whole filament extrusion circle. From there, came our SHR3D IT plastic shredder which later evolved into the all-new GP20 Shredder Hybrid, alongside the Airid Polymer dryer, which enhances the quality of the 3D printing filament.

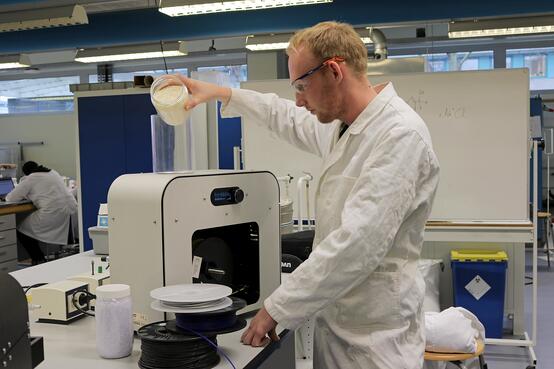

Our goal is to assist the transition of businesses, educational facilities, and research labs to a more sustainable business model — not only from an economic perspective but also from an environmental-friendly practice of 3D printing. We stay focused on this goal by constantly improving our products and searching for ways to take material innovation to the next level.

3devo offers high-performance products and services, that transform filament extrusion into a closed-loop circle. By working with some of the biggest brands in the world, we dare to say that nobody excels in filament extrusion the way we do!

We are dedicated to helping our customers improve their competitive advantage through the customization of enhanced 3D printing filament. We offer the tools and knowledge — all you need to do is use it.

Your experience with 3devo products is our top priority. No exception. We make sure that we treat your issues like our own. Our support platform is full of guides, extrusion resources, and useful tips. Need more? We have a live support team for that. Any time and place with the click of a call.

Potential over Experience! We believe there is a lot more to achieve if you’re willing to learn. That’s why we look for the greatest potential instead of focusing on the most experience.

Be The Change You Seek! Have the courage to solve the problems you find, and spark change. Whether it’s to better our processes, products, people, or place. Finding problems is easy, finding solutions is where it gets difficult/exciting.

Every Client is a Partner! We take ownership of the challenges our clients experience in reaching their goal. We work hard to build a relationship where we can get there together as partners.services.

Focus X Effort = Success! If we focus on the right things and work hard enough we will reach success, no matter how ambitious the plans. Dare to explore.

Freedom with Responsibility! We enjoy the freedom to try new things, and we take ownership of our actions and results. Try and fail, but don’t fail to try.

Research your own 3D printing materials – Unlock the freedom to experiment

From design to development and production, 3devo creates the most complete filament extrusion machines and tools. Using cutting-edge technology, and high-quality European standards, our goal is to make filament extrusion simple for everyone!

Customer care is always the first priority for us. On our online help platform, you will find video tutorials, troubleshooting steps and solutions, and everything else you may need to know about filament extrusion.

3D Printing is a demanding procedure with a focus on detail and we know that. By using the highest quality standards, we make sure that you will be able to recycle your plastics for a long time.

We are never standstill. Innovation is the reason

Our mission is simple – to streamline the process of material research and development

How do we do this? By providing you with the best accessible features with the highest quality components.

Are you ready to join the revolution in material development?

The Composer and Precision Series Filament Makers are specialized, result-oriented machines with industrial quality power. Making polymers simpler than ever to work with, while offering even more possibilities in manufacturing and innovation.

With 3devo’s Filament Makers you’ll be able to set up anywhere you please and start creating your own custom filament in no time.

Being ahead of the curve means utilizing your resources to their maximum extent. Our Filament Makers allow you to be one step ahead and develop a new, 100% unique and original filament.

If you’re a professor and want to teach your students about polymers and filament, then there is no better option than 3devo’s desktop-friendly Filament Makers.

With education in mind, we have created a clean design that is a great learning opportunity. Due to our DevoVision software, you have a range of pre-set options that can easily be accessed, whicch saves you time.

You can visualize the process that materials undergo in order to be extruded as filament, including diameter control, temperature, pullers, and more.

When it comes to businesses, one word comes to mind – saving. With 3devo’s Filament Makers, you save up on resources, save up on time, as well as your industry experts’ time.

When it comes to businesses, one word comes to mind – saving. With 3devo’s Filament Makers, you save up on resources, save up on time, as well as your industry experts’ time.

Our Filament Makers are equipped for fast-paced experiments that will get the answers to your question: “What filament is the best for my business?”

Expand on your horizons by saving resources and utilizing a strategy that has never been used before.

100% customizable filament to meet your production process and resource application needs.

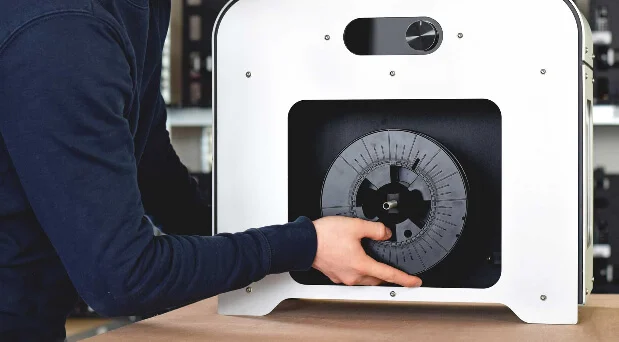

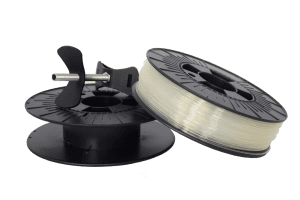

Set your own spool sizes, and with auto spooling let the system to the work. The filament maker will neatly position itself to get a nice-looking spool that won’t tangle.

Fit spools with a max Diameter: of 240mm, And a max width of: 120mm

Fit spools with a max Diameter: of 240mm, And a max width of: 120mm

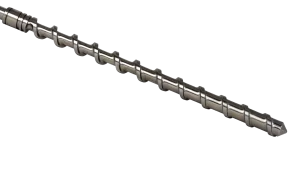

Hardened for Durability. The extruder screw in the Composer is machined for mixing. Its nitride-hardened interior ensures industrial-grade filament extrusion. Enables you to blend different additives, plastics, fibers or powders to create custom filaments.

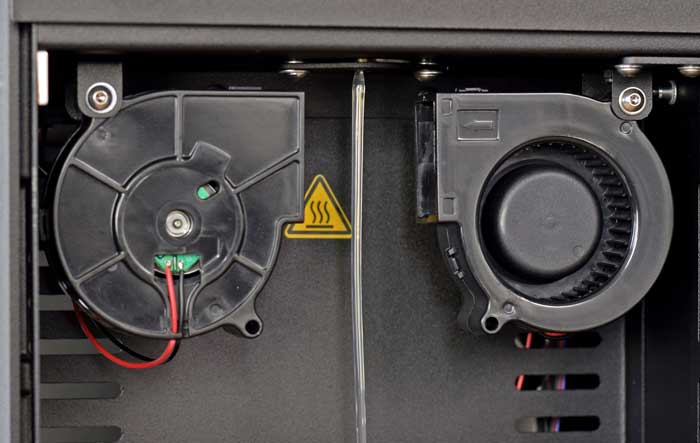

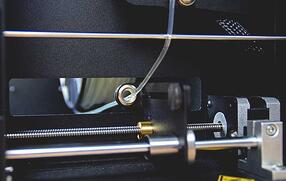

The unique vertical extrusion setup in the filament makers ensures precise roundness and accurately guides the filament to the spool. A dual air cooling system, with adjustable fan speeds and positions, ensures optimal cooling settings for the materials you work with. A sophisticated optical sensor and a dynamic puller system work together to achieve a diameter precision tolerance of +/- 0.05mm*. *(to get the exact diameter tolerance tuning might be needed depending on material type)

Thanks to its swappable spool mount, the filament makers support diverse spool sizes and quick spool changes. Set your custom spool dimensions to get a neatly rolled spool of filament. Adjust the built-in slipper clutch to get the right amount of tension in your filament spool.

DevoVision takes desktop-extrusion to a whole new level. Now, it’s possible to analyze your industry-quality filament in real-time through software integration. Simplifying your workflow while maximizing productivity.

Receive real-time data of constant measurements displaying filament thickness, extruder RPM, puller speed, current filament length and mass, and other settings — all happening simultaneously.

Our application shows an overview of your extrusion history, allowing you to compare previous extrusions to find the settings that work for your application. You can say goodbye to having to estimate and predict certain setting – Now, you simply can retrieve old logs and replicate the same outcome. Desktop extrusion has never been easier.

The data history shows deviation patterns and the overall health of your filament. Providing a clear understanding of the relationship between settings and outcomes is at the heart of the application. DevoVision means less downtime in experimentation and more time implementing findings in production.

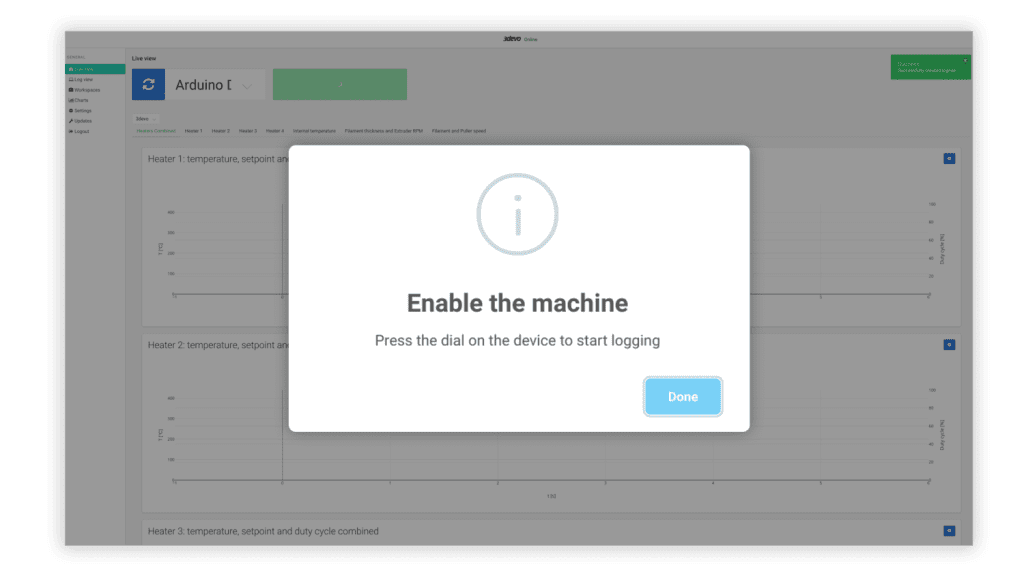

This one-time seamless installation process will have you ready to go as soon as you unbox your filament maker. You’ll immediately be able to jump right in and get started logging your extrusion.

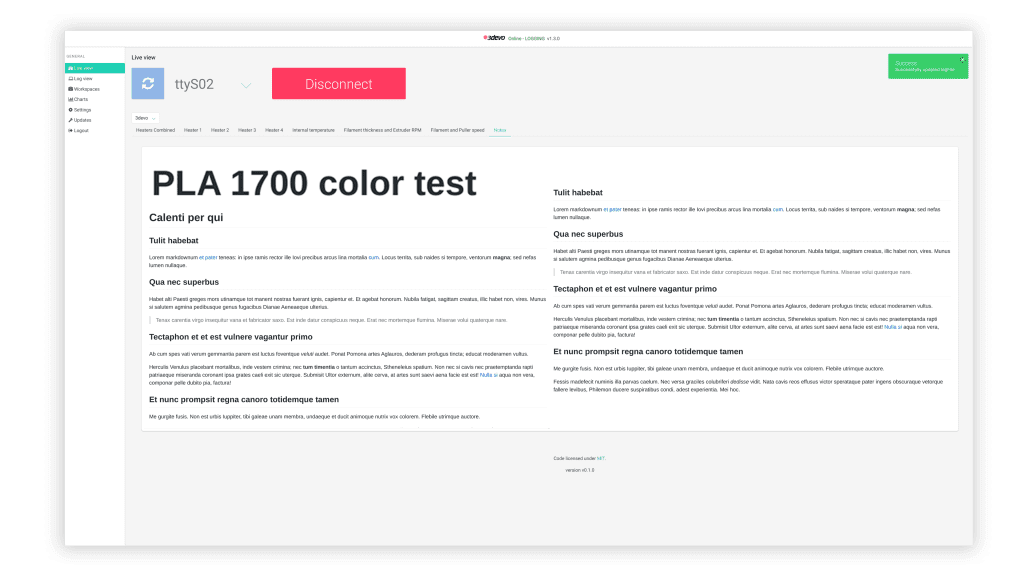

You might come across complications with your extrusion when working with new materials. And that’s okay —it’s simply part of the experimentation process. Thats why we feature a note section. This allows you to annotate the graph as you extrude. Having a place to store your thoughts during experimentation means you can pinpoint a cause and effect between settings and output.

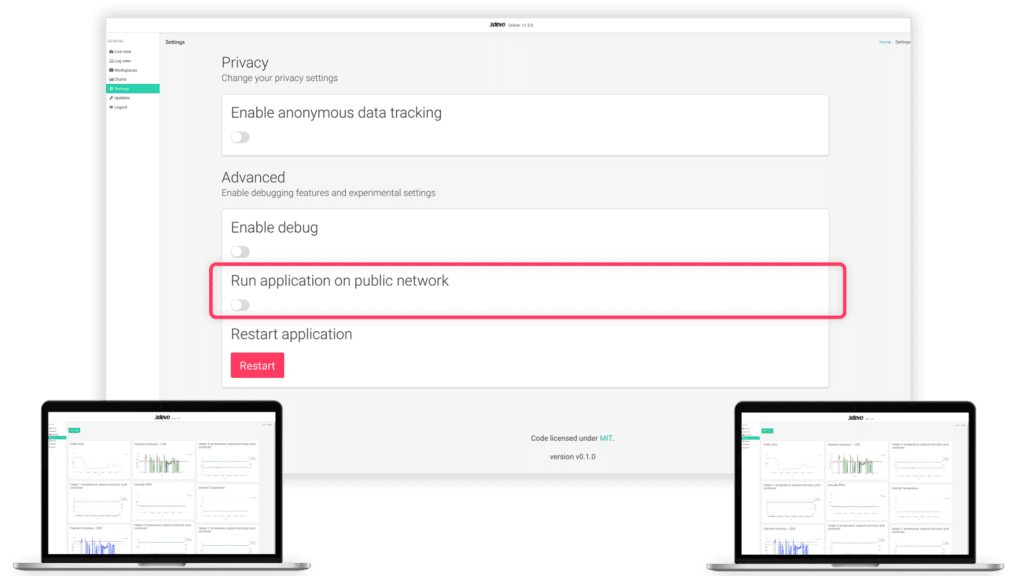

See your extrusion progress from multiple screens within your network. Once you have perfected your extrusion setting, you can monitor your extrusion remotely. You can get on with new tasks while still checking in on your extrusion wherever you are on your network.

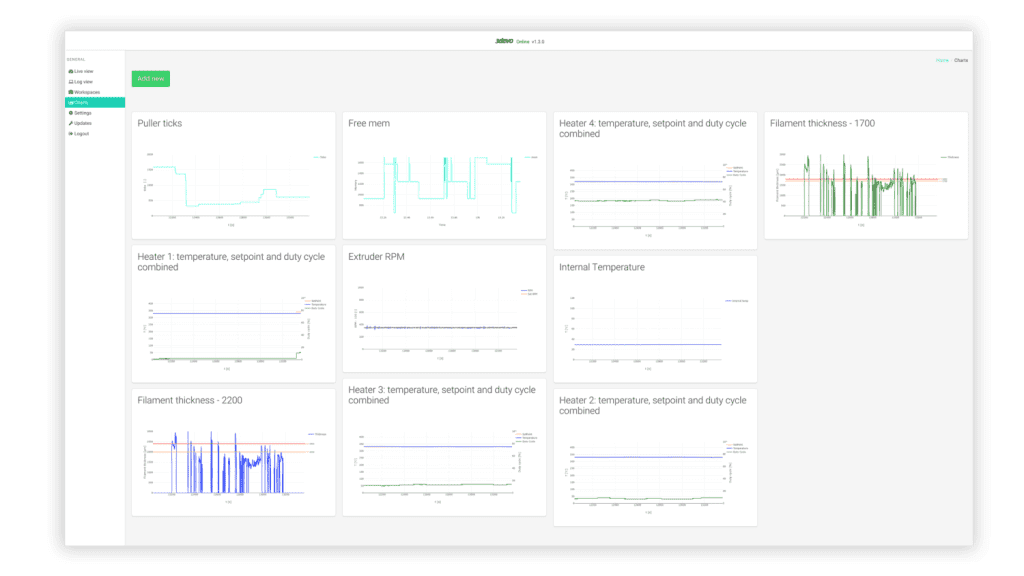

Our workspace displays a clear presentation of extrusion data through a dashboard-like view. You can personalize your workspace with charts that benefit you the most. You can create, clear and comprehensive charts in real-time so results can be demonstrated to others regardless of their extrusion knowledge.

3devo provides the essential tools that combine materials, hardware, and now software.

We do all of this so you can have the most reliable and uninterrupted extrusion experience.

Allowing you to focus on the essentials.

If you require more custom and tailored additive manufacturing solution for yourself or business, please reach out to us via our contact form, call or email. We are more than happy to help you reach your goals with 3d printing technology.

3D APAC Pty Ltd Copyright © 2023. All rights reserved