3D printing with continuous fibers is a new technology that is still improving and maturing. As an emerging additive manufacturing process, its versatility and potential are still being tested. So far, it has proven to be a useful tool for producing parts that have specific qualities – like flexibility, strength, or softness – that cannot be made as efficiently with other processes.

In general terms, Anisoprinting use a process of 3D printing using continuous synthetic fibers as a build material. The resulting composite materials have unique properties not possible with most other methods. In this post, we’ll explain who Anisoprinting is and how they use continuous fibers with other additive manufacturing techniques to produce objects with unique properties.

Anisoprint’s patent-pending technology makes perfect reinforced composite structures through continuous fiber 3D printing. Learn more about the benefits of Anisoprint reinforced composite structures on our blog, where you will find many more insights into why Anisoprint is the future of 3D printing.

Anisoprint is a hardware startup producing high-performance 3D printers for the aerospace, engineering, and additive manufacturing industries. Anisoprint’s new Carbon Fiber 3D Printers allow you to manufacture carbon reinforced plastic parts that can substitute metal ones, reduce costs, all whilst increasing productivity.

Anisoprinting uses a technology called composite printing. Composite filaments are a combination of two or more continuous filaments twisted together, in a lattice pattern. When the filaments are twisted together, the resulting composite material have very interesting properties across the entire print, such as massively increased strength and reduced weight to their metal counterparts.

Anisoprinting can produce objects with composite properties not possible with other 3D printing methods. Why would you want Anisoprinting’s materials in your parts? Here are a few examples of where these materials might be useful. Strength and Toughness are properties that are difficult to achieve with many other 3D printing methods, so composite 3D printing can be very useful if strength is needed. Some materials are useful because they are lightweight, others because they are solid and heavy. Anisotropic printing allows you to produce high tensile strength parts with low weight, meaning aerospace and engineering industries can benefit massively from the parts, where reducing weight of parts and keeping them strong can become an issue.

If you are into additive manufacturing, then this is great news for you. Anisoprint are a part of the 3D printing revolution, developing a technology that allows users to 3D print functional products from composites reinforced with continuous fibers with up to 900 MPa strength

while low weight and perfect surface quality. All available with the touch of a button. These prints are seven times stronger than steel, twenty times stronger than plastic and two times stronger and lighter than aluminium. Allowing for greater use cases in the additive manufacturing world.

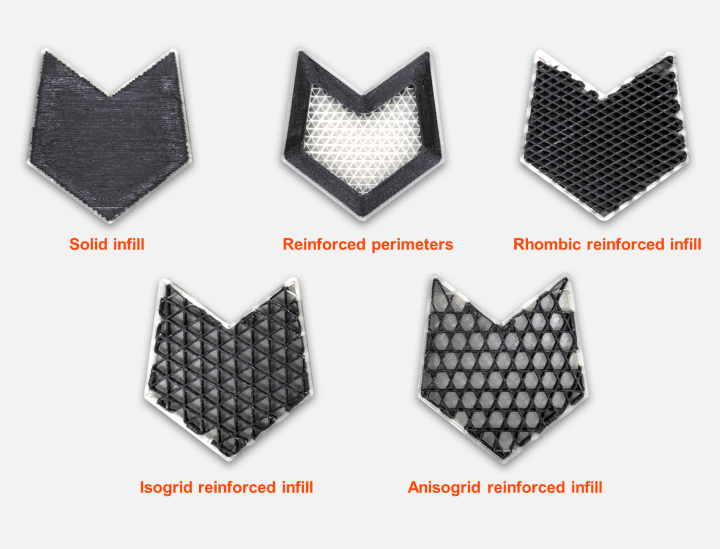

In the Anisoprint advanced composite extruder, it is possible to print complex shapes. It’s a special extruder with two inputs: one for thermoplastic and the other for reinforcing fiber. The fiber can be fed separately or together through the same nozzle, allowing you to vary fiber volume ratio and lay it by complex curvilinear trajectories. This allows you to print composite parts with lattice inner structure without using large amounts of material, reducing weight and production time.

As a result, you get a bi-matrix composite part of any shape, without tools, molds, machining or post-processing. This will bring down production times considerably, allowing for faster interactions, production, and work.

THE PROM IS 500

Easier, faster and cheaper manufacturing process with high-strength parts from continuous fiber reinforced composites. Industrial CNC, industrial standards: reliability, repeatability, precision, and safety. The PROM IS 500 is the perfect solution to your manufacturing problems.

It features high temperatures up to 400 °C, a very large build volume of 600 x 420 x 300 mm, an open system which is design to run 24/7 in your workspace, touch screen, Wi-Fi and Ethernet port and USB for loading your files.

3D printing has been used for a number of years to make prototypes and turn them into working products. At 3DAPAC we’re excited to be able to offer Anisoprint technology to bring game changing capability straight to our customers. Contact us today, and we can talk about a solution for your additive manufacturing problems.

We can assist you in using composites to rethink your product design. Contact us today to see how our range of Anisoprint 3D printers can help your business.

3D APAC Pty Ltd Copyright © 2023. All rights reserved