3D Printers are amazing devices, with almost limitless possibilities to create, iterate and prototype to your hearts content. However, just like their 2D counter part, they are prone to small issues and difficulties which can cause headaches for users.

Here we have consolidated some quick and easy fixes to get you on your way!

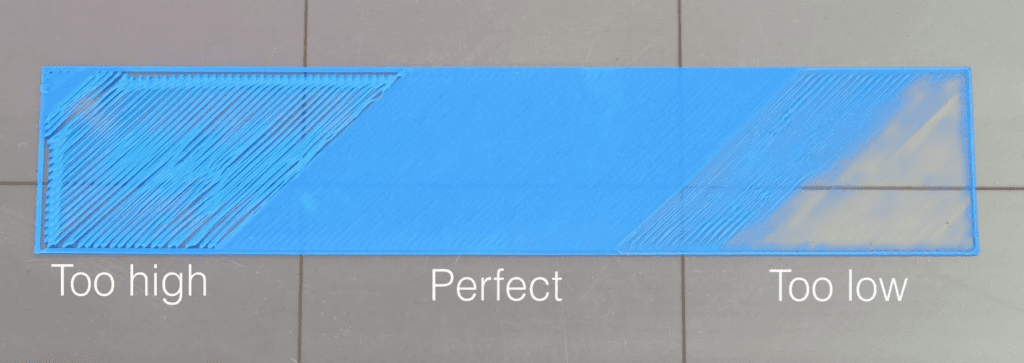

To properly level the bed, you will need to follow these steps:

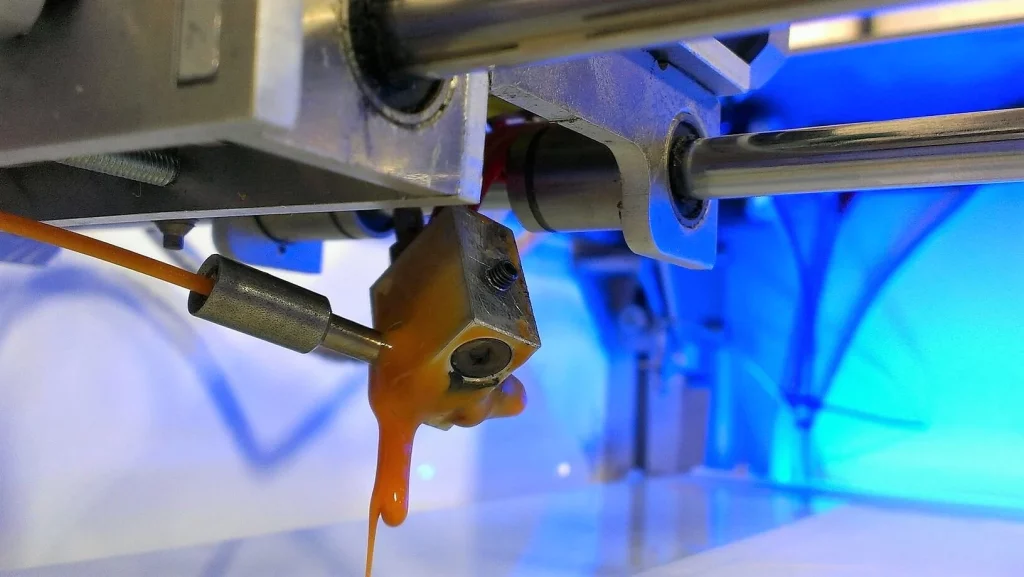

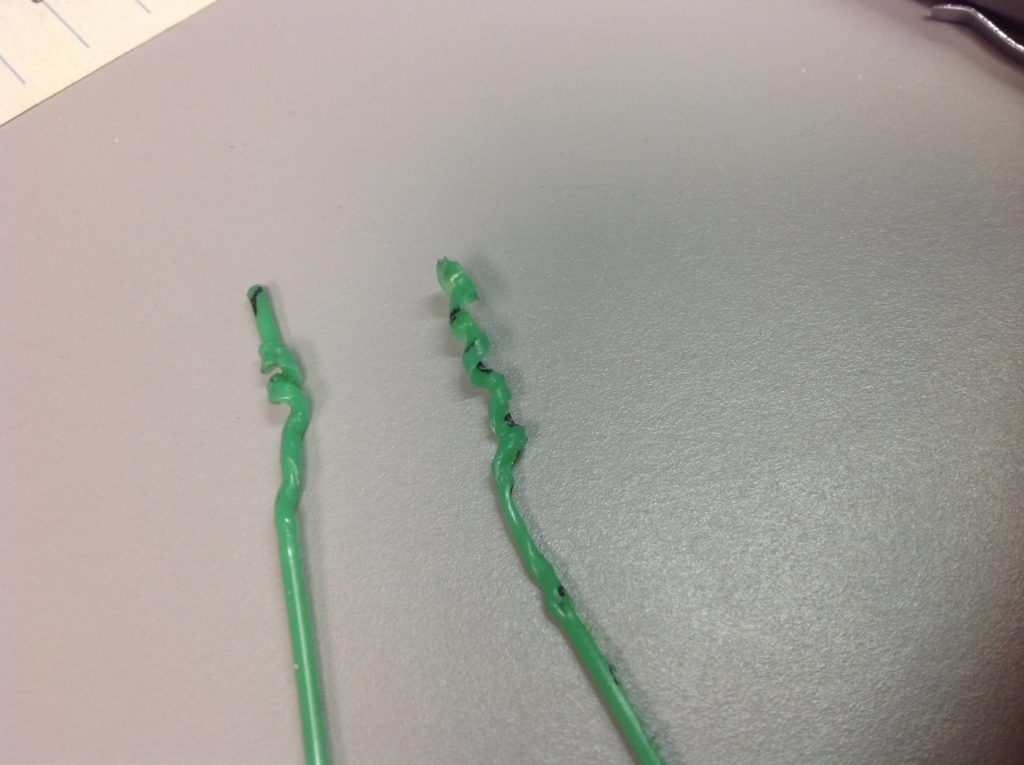

To clear a clogged nozzle, you will need to follow these steps:

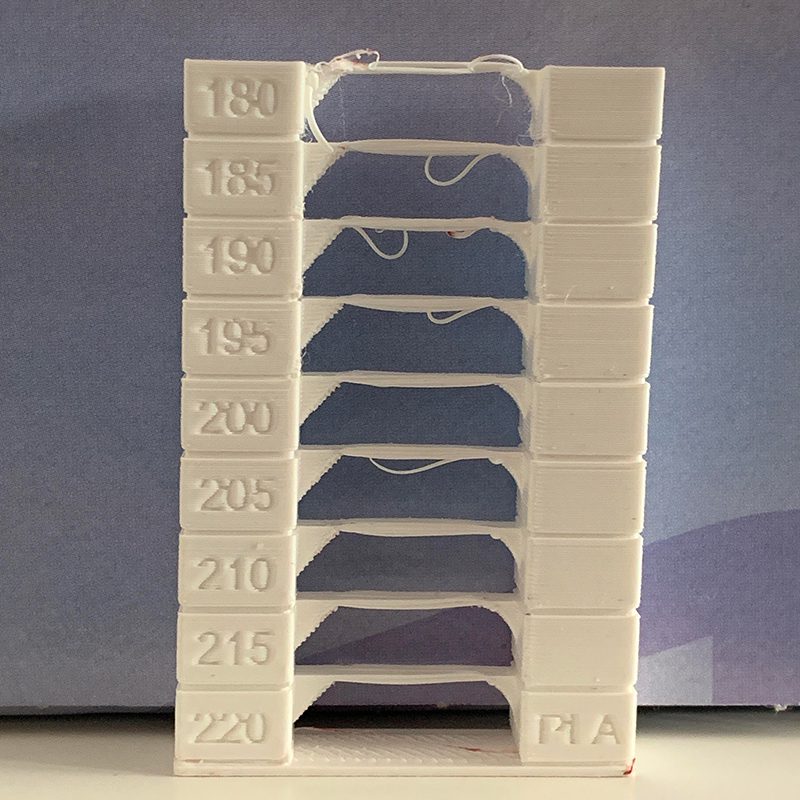

To ensure that the temperature is set correctly, you will need to follow these steps:

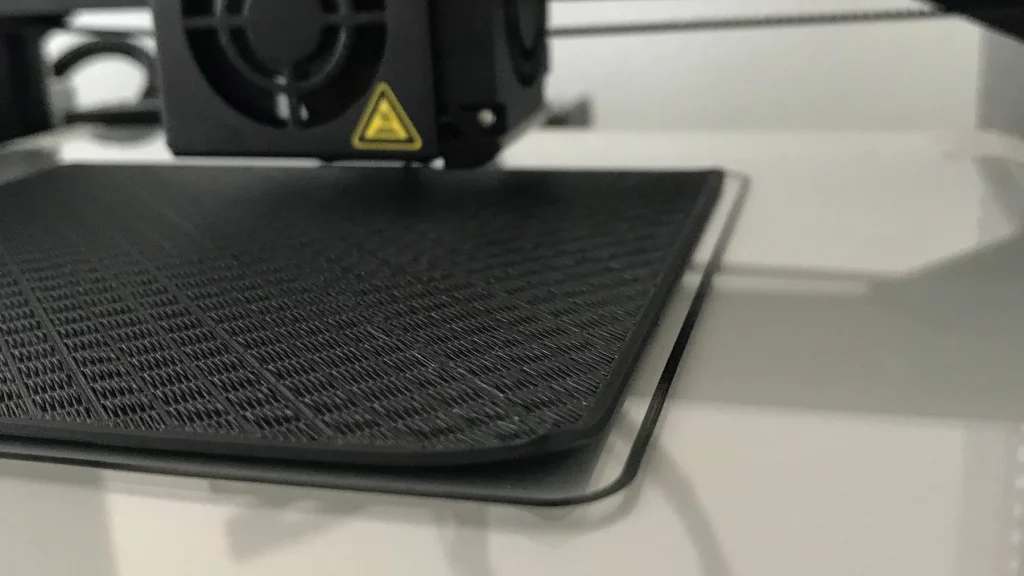

To improve bed adhesion, you will need to follow these steps:

To clear a filament jam, you will need to follow these steps:

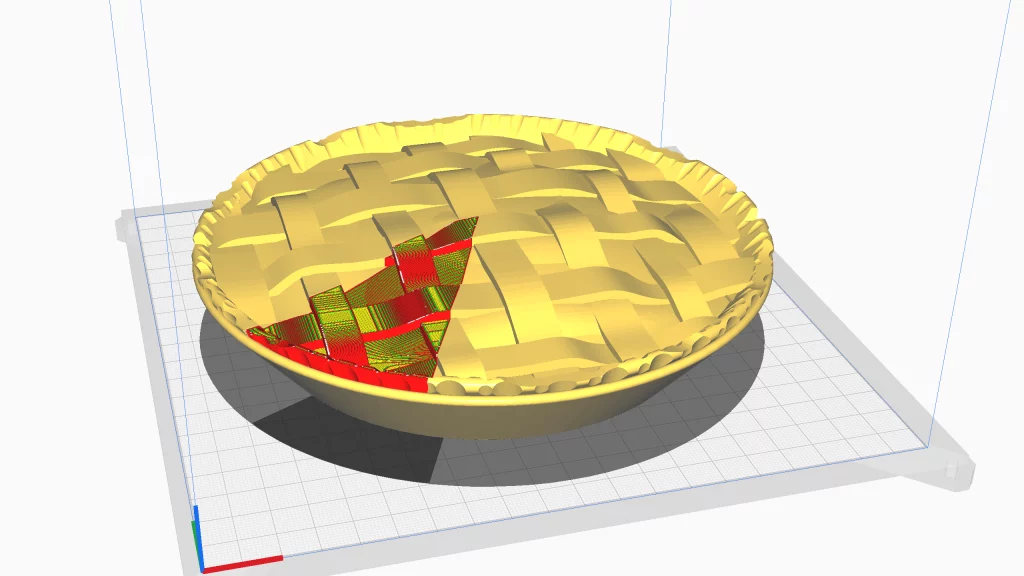

To ensure that the file is compatible with your printer and slicing software, you will need to follow these steps:

It’s important to note that each printer model can have different instructions and troubleshooting steps, so it’s always a good idea to consult the printer’s manual or the manufacturer’s website for specific instructions. Additionally, if you are still having issues after trying these troubleshooting steps, it may be necessary to seek assistance from a more experienced user or professional technician.

3D APAC Pty Ltd Copyright © 2023. All rights reserved