In today’s competitive business landscape, companies are constantly seeking new ways to streamline their operations, improve efficiency, and reduce time to market. Enter 3D printing technology: a powerful tool that is transforming industries worldwide by accelerating product development and enabling rapid prototyping. The adoption of 3D printing, or additive manufacturing, is opening up a new world of possibilities, enabling businesses to bring innovative products to market faster, iterate designs more efficiently, and ultimately gain a competitive edge.

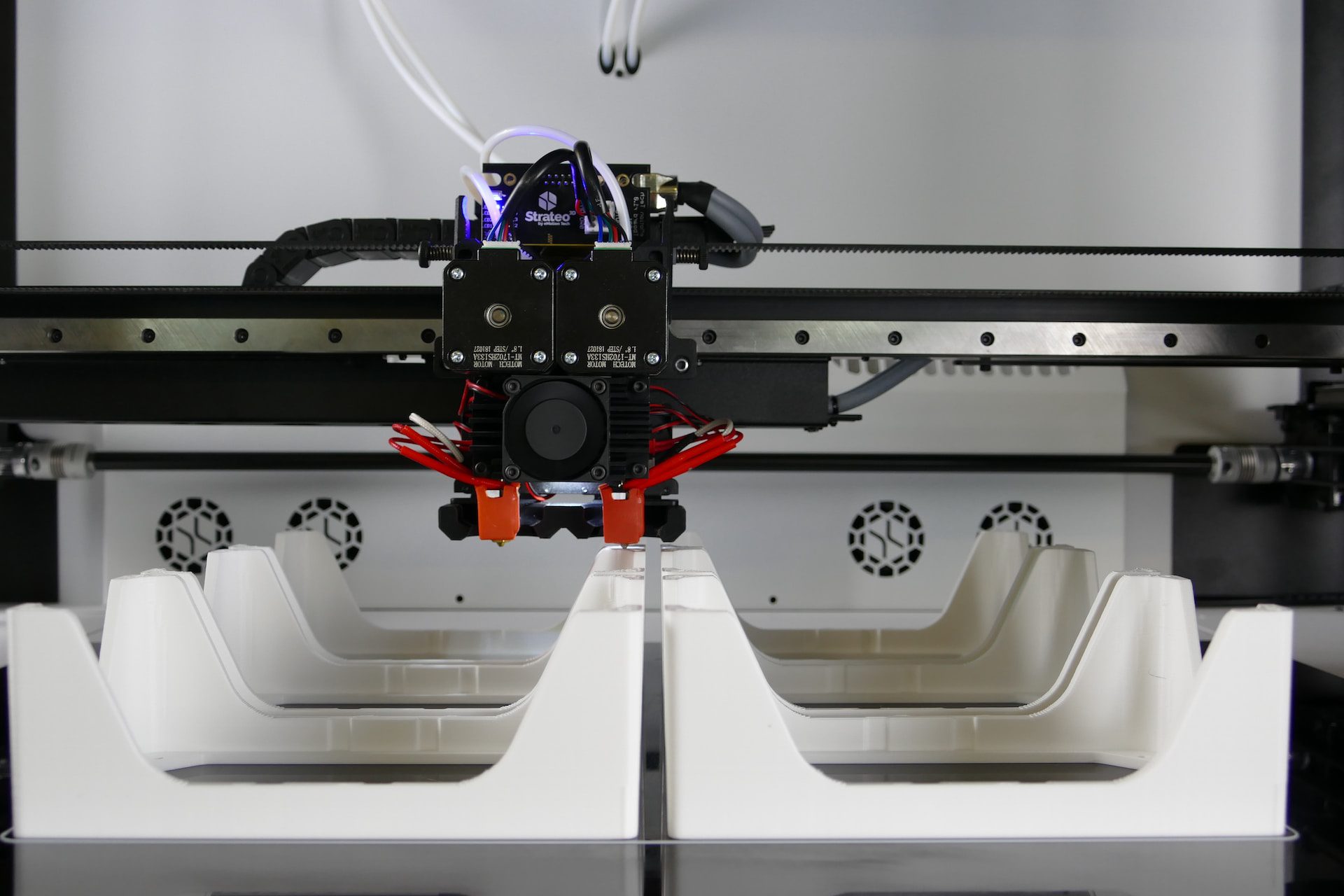

3D printing is a process that creates three-dimensional objects by depositing layers of material according to a digital design file. This technology allows businesses to transform their ideas into tangible products with unparalleled precision, speed, and flexibility. Whether creating prototypes, manufacturing small runs of customised products, or even producing complex, large-scale items, 3D printing offers a range of benefits that make it an attractive and indispensable tool for businesses involved in product development and manufacturing.

In this article, we will delve into the world of 3D printing and explore how it is revolutionising the product development process for businesses across diverse industries. From rapid prototyping and design iteration to optimising manufacturing workflows and reducing costs, discover the game-changing impact of 3D printing technology on the Australian business landscape.

One of the most significant advantages of 3D printing technology in the product development process is the ability to create functional prototypes rapidly. Traditional prototyping methods can be time-consuming and costly, with multiple iterations and revisions often required before the final design is approved. However, 3D printing enables businesses to produce highly accurate and intricately detailed prototypes within a matter of hours or days, significantly shortening the design phase and allowing companies to make faster, more informed decisions about their products.

With rapid prototyping, businesses can identify design flaws or areas for improvement early in the process, reducing the risk of costly delays or changes during the manufacturing stage. In turn, this accelerated approach to prototyping ensures a faster time to market, improving overall business efficiency and responsiveness in an increasingly competitive market.

3D printing technology allows businesses to embrace an iterative approach to design, refining their products more quickly and cost-effectively than traditional manufacturing methods. The ease with which design revisions can be made and tested using 3D printing enables companies to perfect their products and ensure optimal functionality and aesthetics, leading to increased customer satisfaction and higher product quality overall.

Furthermore, 3D printing offers unparalleled customisation capabilities, allowing businesses to produce bespoke or personalised items that cater to specific customer preferences and needs. By utilising the flexibility of 3D printing, companies can differentiate themselves from competitors, tap into niche markets, and build strong customer loyalty, all while streamlining their product development processes.

Beyond prototyping and design, 3D printing technology also has the potential to revolutionise the manufacturing sector. By integrating 3D printing into their production workflows, businesses can achieve greater production efficiency, reduce material waste, and even produce complex components that may be impossible or expensive to create using traditional manufacturing methods.

In addition, 3D printing can be a powerful tool in on-demand manufacturing, where products are produced only when required, minimising inventory costs and reducing the need for warehouse space. Businesses can thus respond nimbly to changing consumer demands and market trends, while also benefiting from reduced overhead costs and improved cash flow.

The adoption of 3D printing technology in the product development process can lead to significant cost savings for businesses, both in the short and long term. By reducing the time and resources required to create and refine prototypes, companies can minimise their upfront investment in product development, while the ability to produce complex, customised components with precision and efficiency can lead to lower production costs overall.

Moreover, the reduced waste associated with 3D printing and the potential for on-demand manufacturing contributes to a more sustainable and environmentally-conscious approach to product development. By adopting 3D printing technology, businesses can reduce their carbon footprint, conserve resources, and demonstrate their commitment to environmental responsibility, ultimately benefiting both their bottom line and their brand reputation.

The transformative impact of 3D printing technology on the product development process cannot be overstated, offering businesses across diverse industries a competitive edge through rapid prototyping, design iteration, customisation, and optimised manufacturing workflows. By leveraging the potential of 3D printing, Australian businesses can accelerate the pace of innovation, bolster their market presence, and ultimately drive economic growth in the face of global competition.

Leading providers of 3D printing services and supplies, such as 3D APAC in Sydney and across Australia, are empowering businesses to harness the potential of this cutting-edge technology, offering reliable and comprehensive support throughout every stage of the product development journey. With our expert guidance and support, businesses can navigate the rapidly evolving world of 3D printing, unlocking new opportunities for growth, and setting the stage for a brighter, more innovative future. Contact us today to explore how 3D printing can revolutionise your product development process and drive your business forward!

3D APAC Pty Ltd Copyright © 2023. All rights reserved