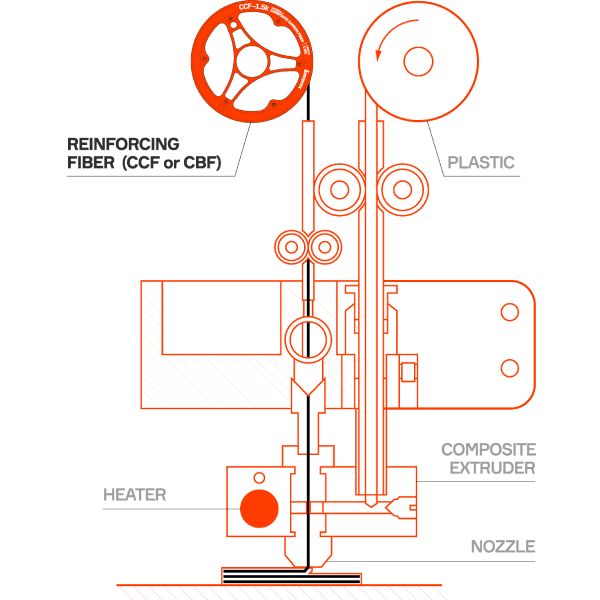

CONTINUOUS FIBER 3D PRINTING

Anisoprint is the technology for manufacturing optimised composite structures through continuous fiber 3D printing. Printing reinforced lattice structures: lower weight, price and production time.

Anisoprint A4 | 297 mm х 210 mm х 140 mm

Anisoprint A3 | 460 mm х 297 mm х 210 mm

– PEEK (polyetheretherketone)

– PEI (Polyetherimide)

– Made for 24/7 running in a factory environment

– Custom trajectories of fiber laying

– Freedom in materials choice: any plastic as a matrix

– Open G-code

– Non-cloud software

– Printing lattice structures: the most optimal shape for composites

– Getting maximum strength spending minimum material

– 30 times stronger than plastic

– 7 times lighter than steel

– 2 times stronger and lighter than aluminum

If you require more custom and tailored additive manufacturing solution for yourself or business, please reach out to us via our contact form, call or email. We are more than happy to help you reach your goals with 3d printing technology.

3D APAC Pty Ltd Copyright © 2023. All rights reserved