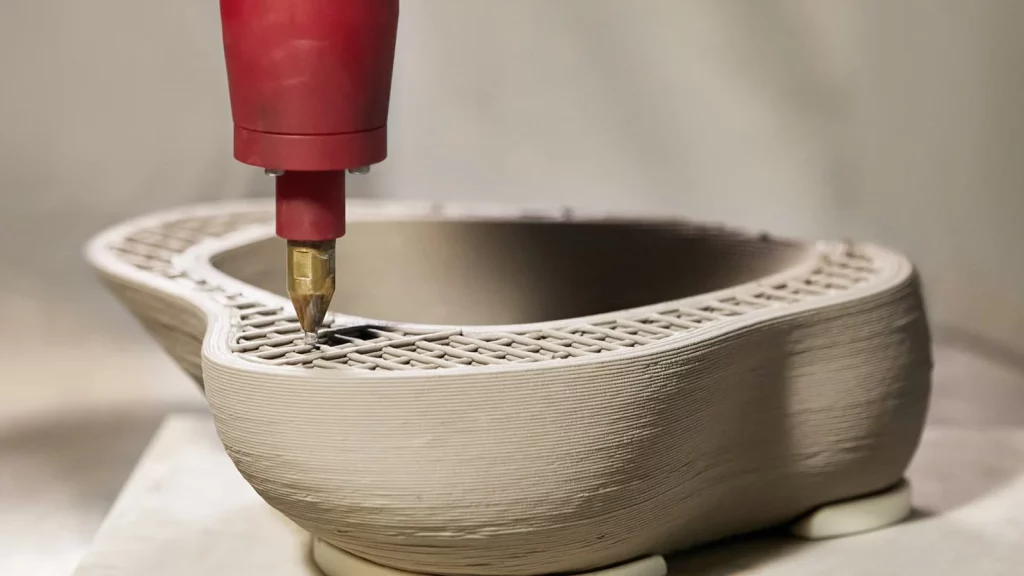

Making real products from digital models is a method known as 3D printing, commonly referred to as additive manufacturing.3D printing creates products layer by layer as opposed to conventional manufacturing processes, which entail cutting, shaping, or moulding material.

This enables the construction of intricate interior structures and geometries that are not feasible using conventional techniques.

Prototyping is one of the most popular applications for 3D printing.

This enables quick and simple prototyping for product design and development, which can significantly boost productivity and cut costs.

Additionally, unique parts for a variety of industries, including aerospace and medical devices, can be produced via 3D printing. The healthcare sector is a significant area for 3D printing. This technology enables the more affordable and precise manufacture of dental implants, prosthetic limbs, and other medical items. Additionally, surgical guidelines and models for planning and practising complex surgeries can be made using 3D printing.

Building components and architectural models are both produced using 3D printing in architecture. Additionally, it is utilized to produce distinctive and elaborate designs in the food and jewellery industries. Models and prototypes can be produced using 3D printing in education to support instruction and learning.

Using 3D printing, the aircraft sector is also producing intricate and lightweight parts. The automotive sector uses 3D printing to produce specialized parts like gears and engine parts. Furthermore, sculptures and other works of art are being produced using 3D printing.

There are numerous technologies available for 3D printing, including fused deposition modelling (FDM), stereolithography (SLA), and selective laser sintering (SLS). It’s critical to understand the many types of technology and which one would be most appropriate for a given project because each one has a unique set of capabilities and restrictions.

In addition, a number of materials, including ceramics, metals, and polymers, can be used for 3D printing. It’s crucial to understand the various materials and which one would be appropriate for a certain project because each one has unique features and limits.

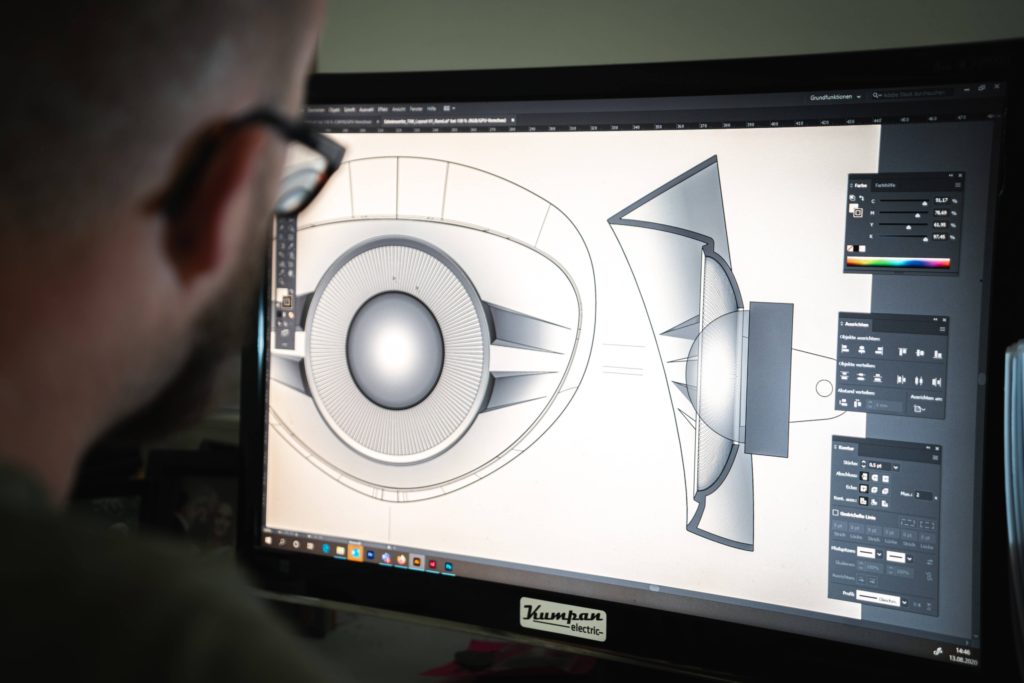

Understanding the fundamentals of computer-aided design (CAD) and the software used to produce 3D models is crucial before getting started with 3D printing.

Software options ranging from free to expensive include Tinkercad, SketchUp, and AutoCAD. 3D models can be produced with this software and then set up for printing.

You can begin studying about the particular printer that you will be utilising once you have a solid grasp of the fundamentals of 3D printing. Learning about the printer’s capabilities, software, and upkeep needs is part of this.

Experimenting and practising are the greatest ways to learn 3D printing.

Make simple models at first, then progress to more intricate designs. Try out several tools, programmes, and settings to see what seems most comfortable. You can begin experimenting with other projects and applications as your experience grows.

In general, 3D printing is a rapidly developing technology that could disrupt a wide range of sectors and alter how we live and work. It provides a broad range of opportunities, from prototyping to specialised production, from healthcare to art and design, and from aerospace to common home items. There are a lot of online resources, such as tutorials, forums, and online courses, that you may use to learn more about 3D printing.

3D APAC Pty Ltd Copyright © 2023. All rights reserved