Professionals who need exquisite dexterity in their work may suffer physically from disorders like rheumatoid arthritis or accidents to their joints, which could possibly end their careers. However, there may be some hope in sight owing to a specialized cooperation from the Fraunhofer Institute, AI, and some good ol’ 3D printing.

Five Fraunhofer institutions collaborate to create the FingerKIt Consortium, which employs AI to create customized, 3D-printed joint implants that can replace these delicate finger components as needed.

The institutes in question are the Institute for Digital Medicine, the Institute for Toxicology and Experimental Medicine, the Institute for Ceramic Technologies and Systems, the Institute for Additive Manufacturing Technologies, and the Institute for Toxicology and Experimental Medicine (MEVIS). Each group contributed knowledge from their specialized field to the initiative, providing patients with a way forward who are suffering from a variety of joint-related conditions.

There are currently few therapy options available if a finger joint becomes dysfunctional as a result of an accident or injury. A joint fusion operation is carried out in most cases.

Surgery is typically used to complete this arthrodesis procedure. The injured joint is manually straightened during the treatment, the cartilage is removed, and the bones are stabilized for long enough for a spontaneous fusion to take place.

As you may guess, this results in a finger that does not bend, which can substantially lower the patient’s quality.

The choices are constrained when conventional implants are utilized. A silicone implant is an option for patients, but it runs the risk of coming loose and requiring additional surgery to fix. Alternatively, patients can choose a standard implant, which, as the name suggests, is only offered in a few conventional sizes and does not completely restore the full range of motion to the affected finger.

Therefore, the best option is one that stays clear of both of these drawbacks of the conventional implant. The optimal joint, then, is one that prevents loosening and permits the finger to regain its full range of motion. The best answer for this is a unique one.

With their AI-assisted, 3D printed joints, the FingerKIt Consortium has effectively proved this.

The workflow created by the engineers and scientists at Fraunhofer is mostly automated and eliminates a lot of the manual labour normally involved in such highly tailored work.

The researchers have created software that applies AI to turn 2D X-ray scans of the finger bones and joints into 3D models. The 3D model can then be used to virtually fix any damage to the joints.

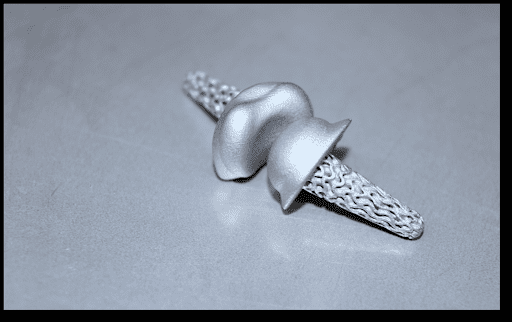

The individual implant design is subsequently derived from the finger model using AI by the Fraunhofer IAPT (AM group) researchers, who then send it for 3D printing.

The new joints are then produced using a high-resolution metal binder jetting method. The green components are then shipped to Fraunhofer IKTS for sintering, where they are consolidated and made denser. To eliminate friction and enable better movement when implanted into the patient, the nearly net-shaped section can subsequently be sent for completion.

The biocompatibility of the materials and the approval of the implants have been handled by Fraunhofer ITEM (toxicology group), while Fraunhofer IWM (mechanics of materials group) has been carrying out the mechanical simulation of the pieces.

The novel workflow developed by the Fraunhofer consortium can manufacture and implant highly customized pieces in just 60% of the time required by conventional methods. As a result, the full procedure—from X-ray to implant—might be finished in a matter of days. As a result, hospital stays would be shorter, which would lower overall inpatient costs.

This process is beneficial for more than just crooked fingers. Patients with missing bones or smaller joints can also use it.

For many, this is good news. The Fraunhofer technique could be used to treat the two percent of adult Germans who have inflammatory rheumatic disorders, according to the German Society for Rheumatology.

“FingerKIt could completely change the treatment of rheumatoid arthritis, for example. Personalized implants could become the gold standard,” said Imgrund.

The FingerKIt project’s technological development has now reached a stage of maturity where the method and product are ready for the market.

The consortium is currently trying to get the required approvals, and it is also looking for business collaborations in the field of medical engineering that can aid in bringing FingerKIt to market.

In conclusion, the FingerKIt Consortium has developed a promising solution for treating dysfunctional finger joints through the use of AI-assisted, 3D printed implants. The process is highly efficient, taking only 60% of the time required by conventional methods, and has the potential to be used to treat a variety of conditions including rheumatoid arthritis. The consortium is currently seeking approvals and partnerships to bring the technology to market.

3D APAC Pty Ltd Copyright © 2023. All rights reserved