Exploring the Future of Culinary Creativity with 3D Food Printing in Schools, Aged Care, and Hospitality

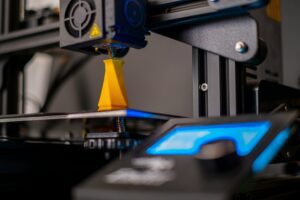

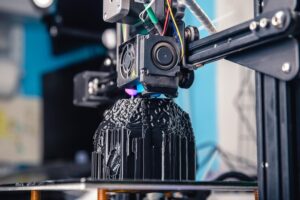

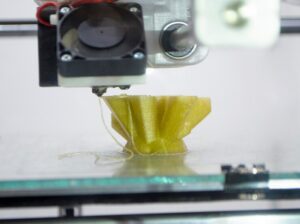

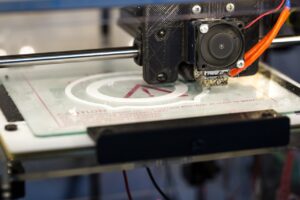

The rapid growth and evolution of 3D printing technology have opened numerous doors in various sectors. One such innovation is the advent of 3D food